Measurement

Undamaged, flat, and properly cleaned sealing surfaces are the basic prerequisite for a permanently leak-tight flange connection. An on-site inspection during operation can already provide initial indications of possible causes based on the leakage pattern.

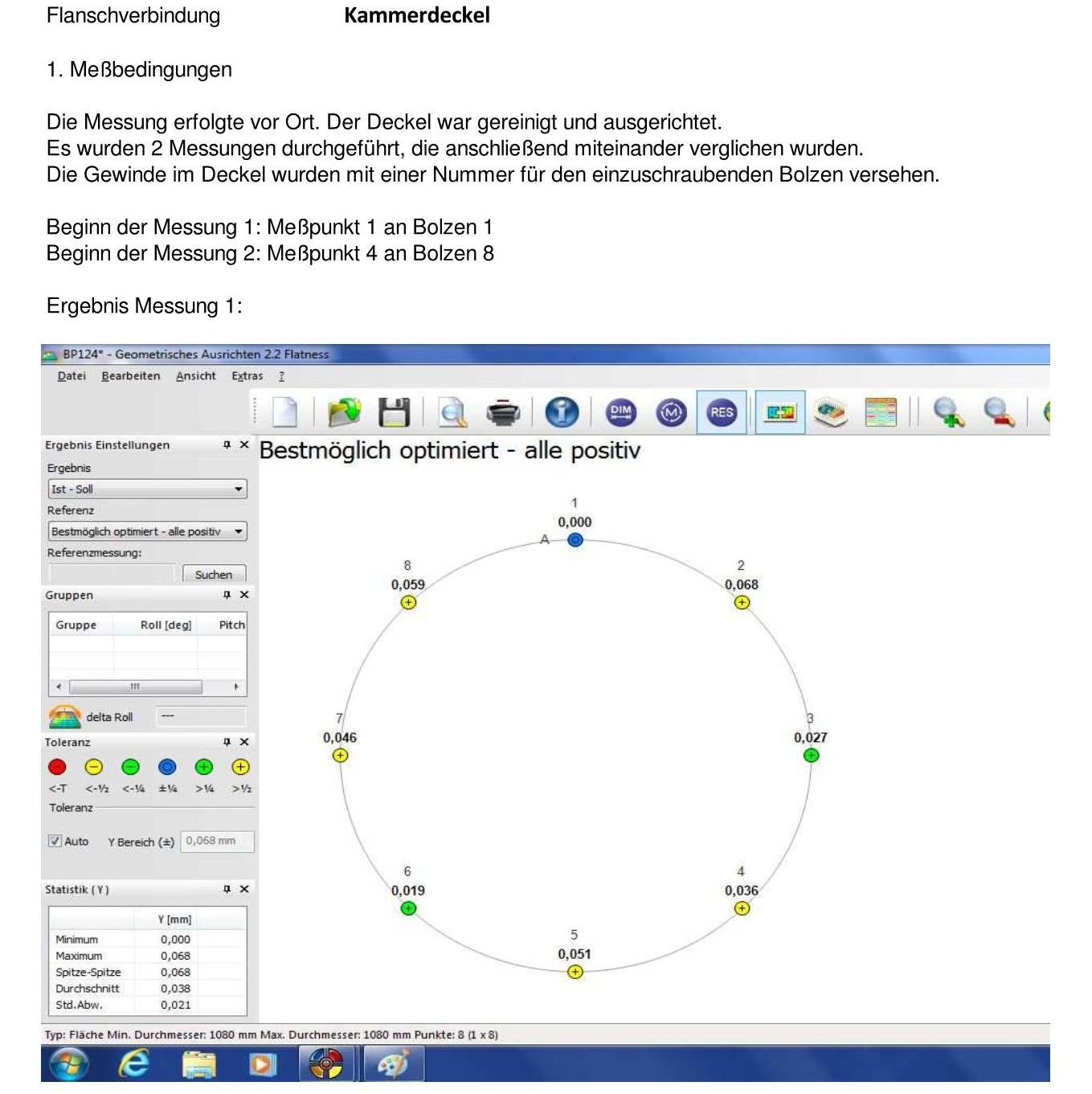

Subsequent on-site measurement of the flange sealing surfaces enables further conclusions regarding potential leakage causes. For small sealing surfaces or grooves, measurements can be carried out using mechanical tools; for large sealing surfaces, laser-optical measurement is recommended.

Laser-optical measurement can be performed with approximately 20 measuring points per sealing surface, including computer analysis, within about 1–2 hours.