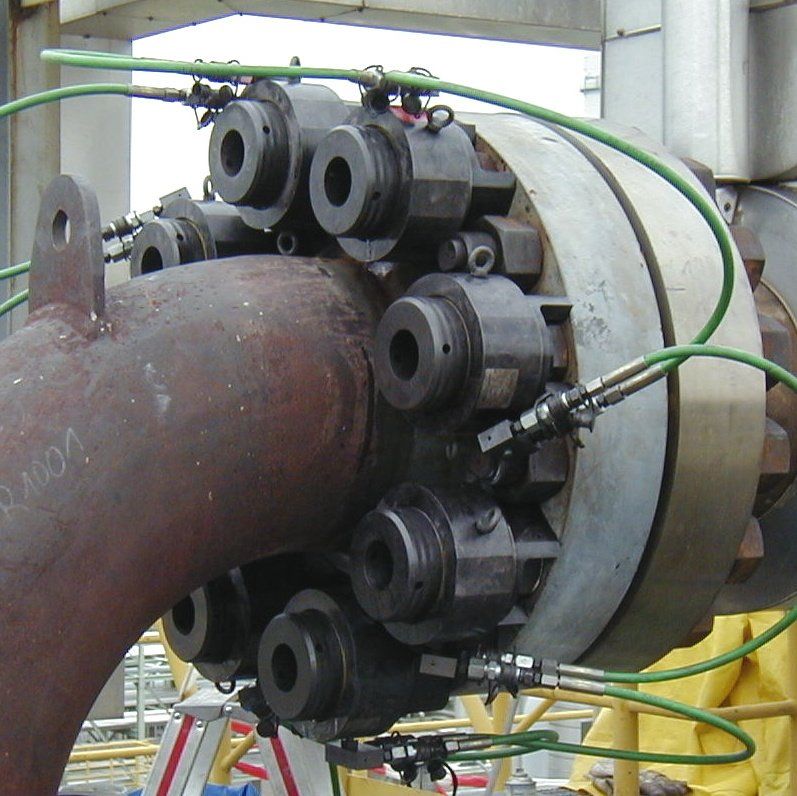

Hydraulic Flange Bolting

The tightening of flange connections using a hydraulic power unit is a proven method in practice, typically applied to bolt sizes from M20 to M48.

With the correct assumptions for friction coefficients and a predefined tightening sequence carried out in multiple steps, the tolerance of the applied preload is approximately ±3% of the calculated installation bolt force.

As an alternative, or as a supplement, bolting in the M20 to M30 range can now also be carried out using electric torque wrenches, achieving the same tolerance range.