Problem Description

Plate heat exchangers lose stress over their lifetime as the inserted rubber gaskets can dry out and crack as well as show signs of settling and plastic deformation.

Requirements for a re-equipment

- Compensation of setting behaviour

- Maintenance of a minimum sealing pressure without overloading the rubber

- Needed lifetime in consultation with the operator

Solutions

- Calculation of optimized bolt forces at installation and the setting behaviour

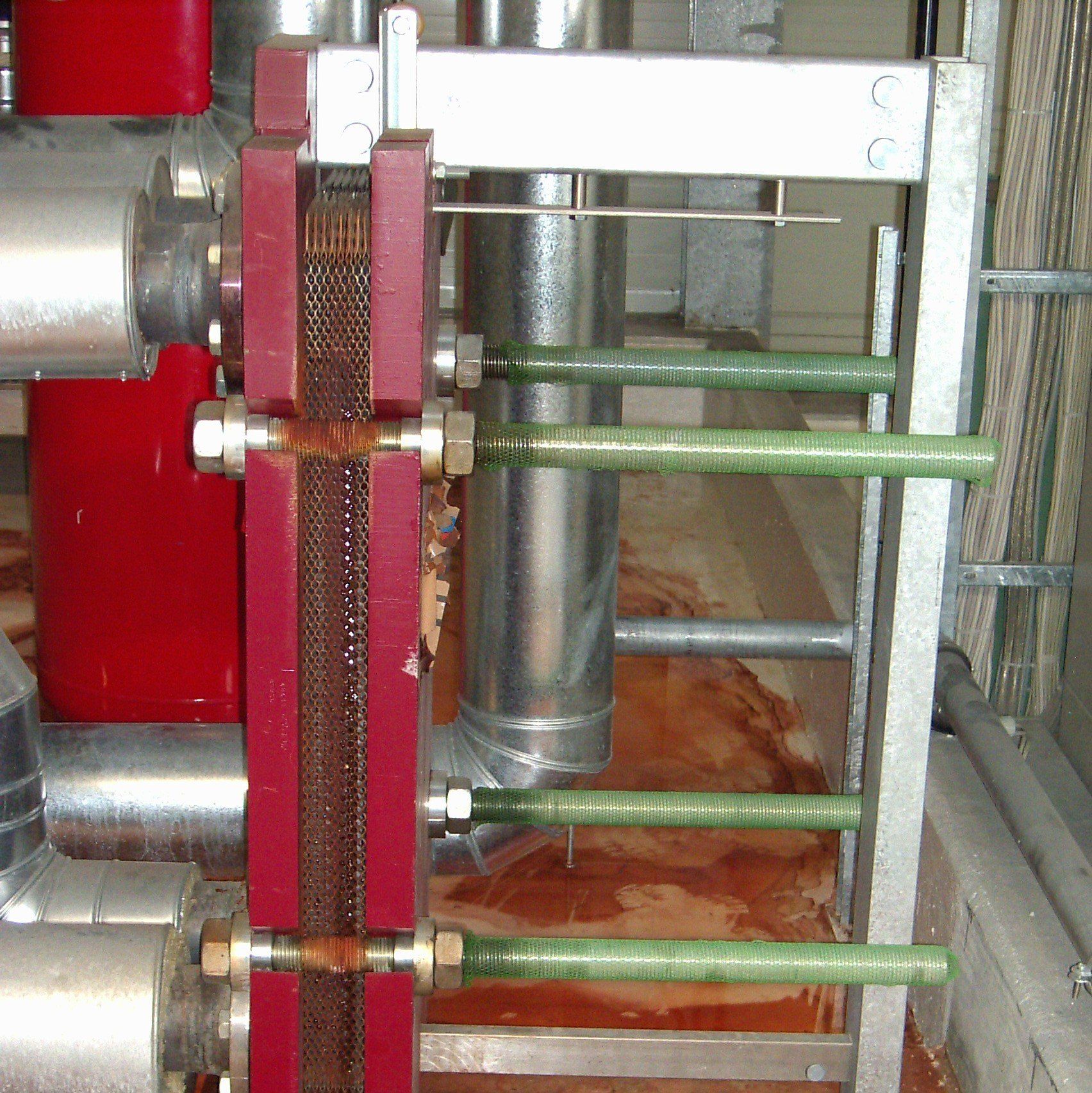

- Use of an additional spring-loaded system using the existing bolts

Design conditions

- Design pressure: up to approx. 20 bar

- Design temperature: up to approx. 150°C

- Gasket size: rectangular up to external dimensions approx. 3000 x 1500 mm

- Bolt size: up to approx. M48