Problem Description

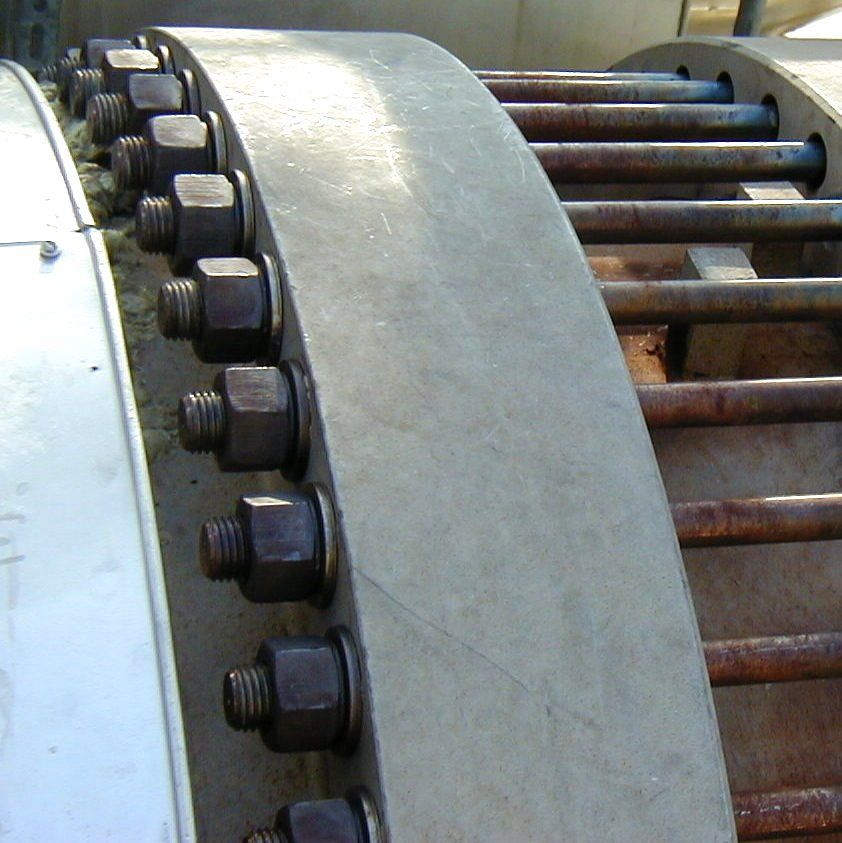

Problems with tube bundle heat exchangers often occur at the tube sheet connection or at the cover. During start-up and shut-down processes, changes in temperature leads to shifts in the sealing system and the sealing pressure falls below the minimum.

Requirements for a re-equipment

- Equipment according to TA-Luft

- Lifetime >6 years

- external checked documentation

Solutions

- Calculation of the optimal / permissible installation screw forces

- Leakage risk assessment based on the calculation results

- Change of gasket width / gasket type / gasket material

- Change in bolt and nut materials

- Change in installation technology

- Use of an additional spring system in case of elasticity problems

Design limits

- Design pressure: up to approx. 400 bar

- Design temperature: up to approx. 750°C

- Gasket diameter: up to approx. 6 meters

- Screw size: up to approx. M110 / 4 inch

Extension of the design limits

With regard to pressure and temperature, the application limits mentioned can be extended after careful examination of the requirements.

Gasket diameters are normally not limited to 2 meters, but for larger diameters, the gasket must be final assembled (welded, coated, fastened to the sealing surface) on site. This should only be done by Ernst Industrietechnik GmbH or specially trained personnel. The largest diameter installed so far was e.g. more than 6 meters (application on a dryer).