Problem description

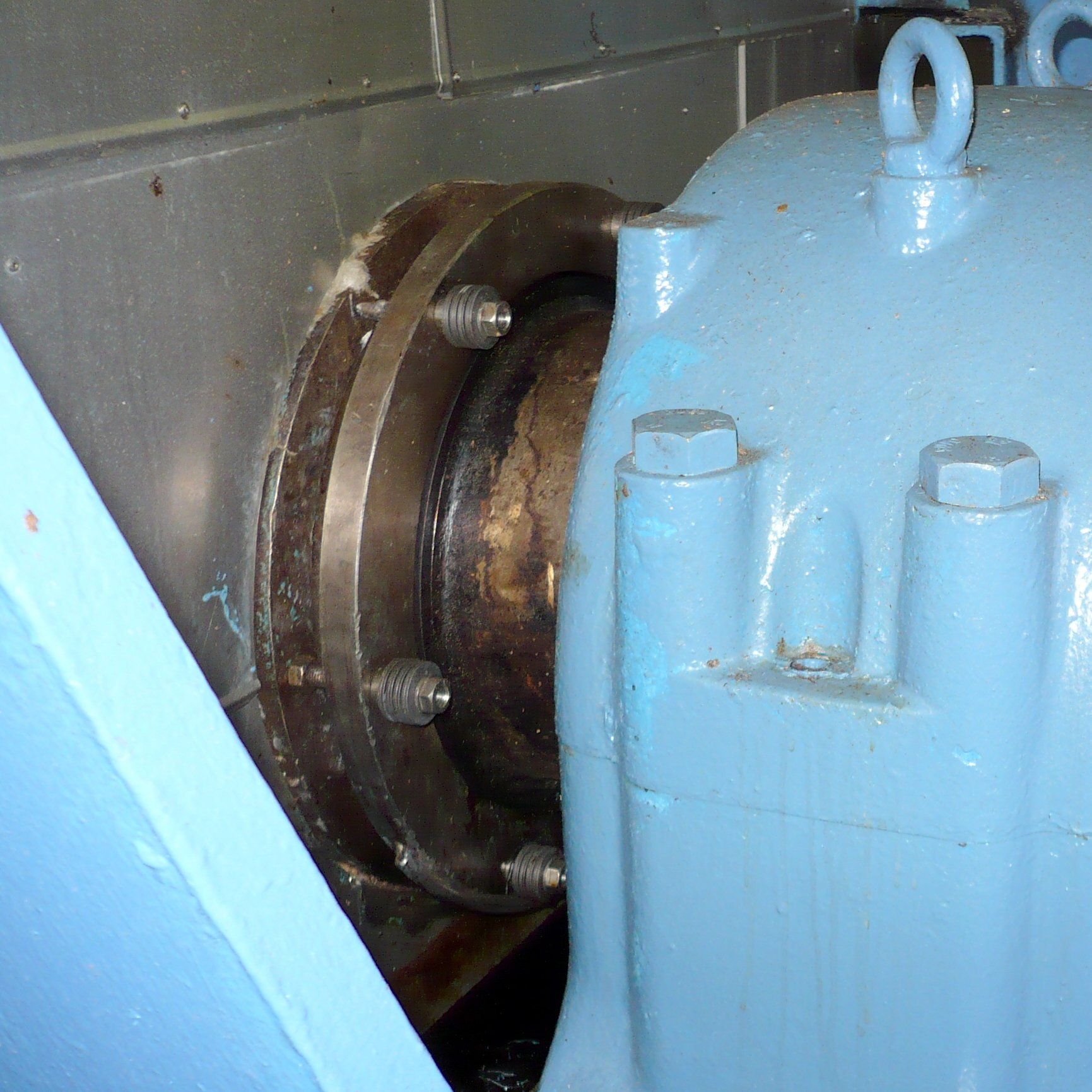

Problems with slow-running shafts mainly occur in the area of the shaft sealing with gland packings. These problems are exacerbated by limitations in the sealing forces, because friction and wear increase with increasing tension in the packing.

Requirements for a re-equipment

- Low (optimized) leakage

- Service interval according to customer requirements

- Insensitivity to changes in operating conditions

- Easy replacement of packing materials

Solutions

- Selection of suitable packing materials

- Calculation of the required and permissible sealing forces

- Estimation of the leakage, which takes into account the product losses but also the cooling of the packing

- Careful adjustment of the packing according to the installation instructions

- Use of additional springs for elasticity and settling problems

- If necessary use of a shaft protection sleeve

Design limits

- Design pressure: up to approx. 40 bar (Increase on request)

- Design temperature: up to approx. 300°C (Increase on request)

- Packing diameter: inside diameter >=6 mm, outside diameter without restriction

- Stuffing box screw size: from M8 (5/16"), up to approx. M36 (1 1/2")