Problem Description

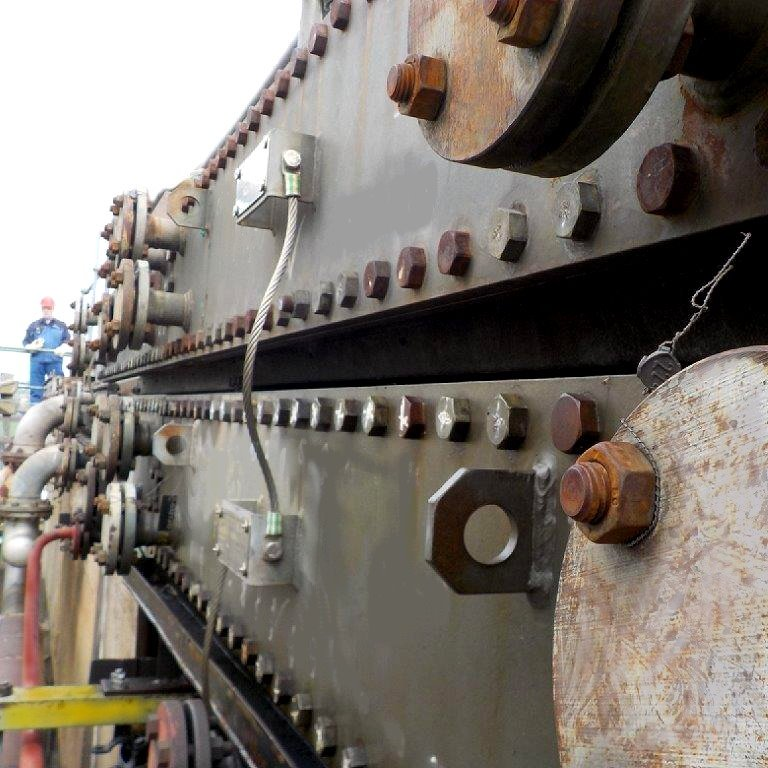

Rectangular flange connections are more difficult to prove mathematically than round flange connections. Furthermore, problems arise with air coolers when the gasket with guide holes is pushed over the bolts, thereby generating only a small sealing pressure and because the cover can be bent easily if the screw force is too high.

Requirements for a re-equipment

- Equipment according to TA-Luft

- Lifetime >6 years

- external checked documentation

- no restriction on the number of start-up and shut-down processes

- flanges free from impermissible deformations

- transverse stress-free installation

Solution

- Calculation of the optimal / permissible installation screw forces

- Reduction of the gasket width

- The gasket is blow-out safed and safe against overloading

- Outer gasket carrier support to prevent flexing of the cover (if space permits)

- Checking and, if necessary, revision of the sealing surfaces

- If necessary, use of additional springs if temperature changes are to be expected

Design limits

- Design pressure: up to approx. 100 bar (extendable on request)

- Design temperature: up to approx. 400°C

- Gasket dimensions: rectangular up to external dimensions approx. 4000 x 1000 mm

- Screw size: up to approx. M48, expandable on request