Replacement Materials

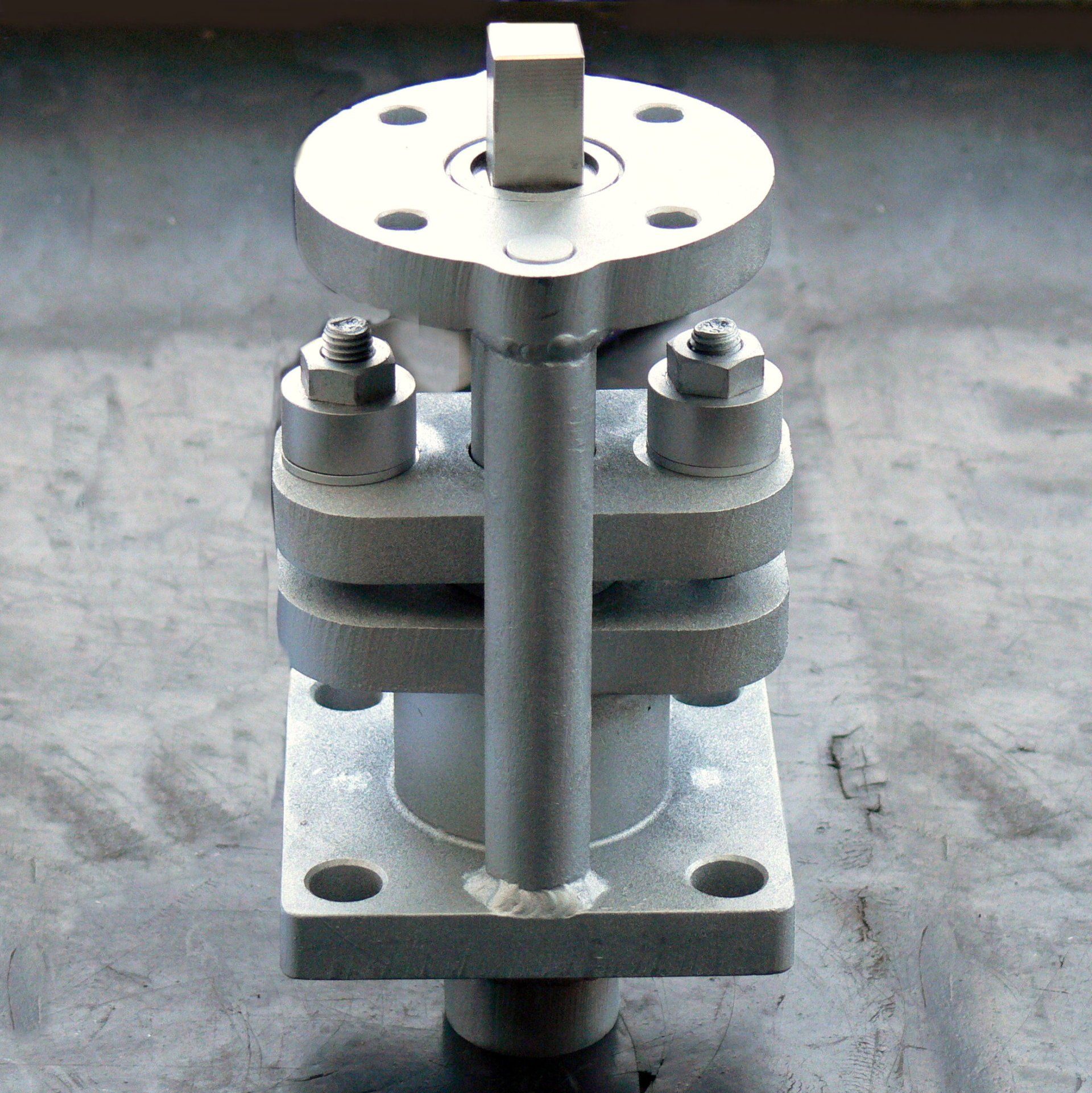

During the overhaul of pumps or valves, packings and gaskets are normally always replaced. Mechanical seals are inspected and then either repaired or replaced.

In many cases, however, it is only after disassembly that it becomes clear which additional components must be replaced.

These include:

- Bearings

- Connecting elements

- Small parts (cotter pins, washers, etc.)

Many of these consumable materials are kept in stock by our company or by our cooperation partners.