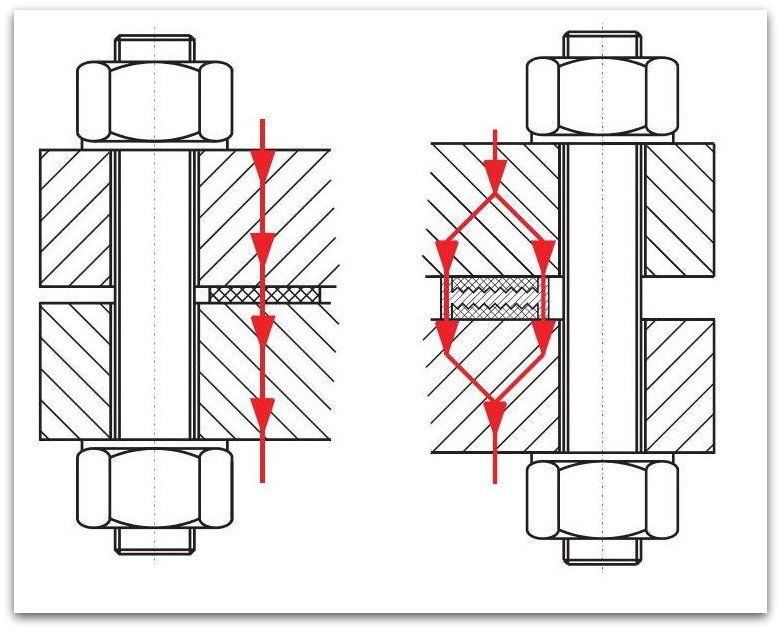

Primary / Secondary frictional connection

In the conventional primary joint (left picture) the connection force of flanges is transmitted through the sealing material.

The secondary frictional connection (right picture) bypasses the introduced force exceeding a definite limit around the gasket so that the laload is subjected to a defined pressing force, and the applied excessive force is exclusively effective as connecting force of metallic components.

This system is described in detail in a separate brochure.